Exhibit 10.22

Proposal for

Actinium Pharmaceuticals, Inc.

225Ac-Labeling of HuM195

March 30, 2007

Prepared by:

IsoTherapeutics Group, LLC

1004 S. Velasco St.

Angleton, TX 77515

|

IsoTherapeutics Group, LLC

|

CONFIDENTIAL |

Page 1 of 10 |

| Propodal for API |

3/30/2007 |

Table of Contents

| Purpose |

3 |

|

Responsibilities

|

3 |

|

API will provide

|

3 |

|

ITG will provide

|

3 |

|

Study Proposal — Executive Summary

|

3 |

|

Study Proposal — Details

|

6 |

|

Stage 1 — Review previous work

|

6 |

|

Stage 2 — Complexation w/ DOTA

|

6 |

|

Stage 3 — Complexation w/ BFC

|

7 |

|

Stage 4 — Conjugation

|

7 |

|

Stage 5 — Label HuM195 w/ 225Ac

|

8 |

|

ITG Consultation Services

|

8 |

|

Time Estimate

|

8 |

|

Cost Estimate and Payment Schedule

|

9 |

|

Cost Estimate

|

9 |

|

Payment Schedule

|

10 |

|

Signatures

|

10 |

|

IsoTherapeutics Group, LLC

|

CONFIDENTIAL |

Page 2 of 10 |

| Propodal for API |

3/30/2007 |

Proposal for Actinium Pharmaceuticals, Inc

225Ac-Labeling of HuM195

Purpose

This is a proposal by IsoTherapeutics Group, LLC (ITG) for Actinium Pharmaceuticals, Inc. (API) to work on the improvement of 225Ac-labeling of HuM195.

Responsibilities

API will provide

●HuM195 monoclonal antibody and applicable information

●225Ac as required

●Applicable data from prior work

●Funding

ITG will provide

● Supplies and materials

●Laboratory facility

●Labor

●Interim and final reports

●Consulting as as requested and authorized by API in writing

Study Proposal Executive Summary

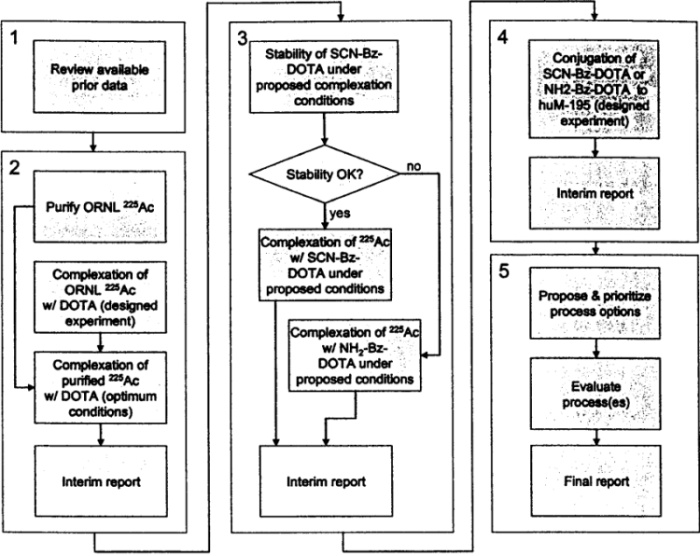

The object of this work is to improve the overall yield of 225Ac labeling of HuM195 monoclonal antibody (mAb). The proposal is staged as indicated in the flow chart (Figure 1) and in the outline below. The proposal is intended to be flexible, with both parties reviewing the results of each Stage prior to initiation of the next Stage. The scope, deliverables, and estimated costs for the next stage will be adjusted as mutually agreed upon prior to initiation of that Stage. The estimated total cost to API for the entire proposal as outlined herein is $112,000. Details on the cost breakdown and payment terms are found in later sections.

In addition to the defined portions of this proposal, ITG will provide, at API's request, additional consulting as needed on matters outside the scope of this proposal. This will be done at an hourly rate of $200.

|

IsoTherapeutics Group, LLC

|

CONFIDENTIAL |

Page 3 of 10 |

| Propodal for API |

3/30/2007 |

|

Figure 1. Flow chart of stages proposal

|

|

The finished radiopharmaceutical is assembled from three parts, the mAb, the bifunctional chelant (BFC), and the 225AC. There are two stepwise ways of accomplishing this, conjugation followed by complexation:

1) mAb + BFC 4 mAb-BFC 2) mAb-BFC + n5Ac mAb-BFC-225Ac

or complexation followed by conjugation:

1) BFC + 225AC --> BFC-225AC 2) mAb + BFC-225Ac 4 mAb-BFC-225Ac

The former method may be preferable from a manufacturing standpoint; however, the best results to date have been by the later approach. This proposal will explore both methods with the goal being maximization of 225Ac labeling yield.

In Stage 1, all available data from prior work will be reviewed. This includes work done by Memorial Sloan-Kettering Cancer Center (MSKCC), Oak Ridge National Laboratory (ORNL), and The Dow Chemical Company (Dow).

|

|

IsoTherapeutics Group, LLC

|

CONFIDENTIAL |

Page 4 of 10 |

| Propodal for API |

3/30/2007 |

In Stage 2, complexation conditions for 225AC will be optimized in a designed experiment using DOTA, a surrogate for the bifunctional chelating agent (BFC) SCN-Bz-DOTA. Additionally, 225AC will be purified and this purified "-*Ac will be complexed using the optimized conditions.

In Stage 3, the stability of the SCN-Bz-DOTA BFC will be evaluated under the conditions found to be optimum for 225AC complexation. If stability is an issue, i.e. if the BFC degrades under conditions required to obtain significant 225AC complex, then an alternative conjugation procedure involving the in situ formation of SCN-Bz-DOTA from NH2-Bz-DOTA will be investigated. Complexation of 225AC using the BFC(s) will be performed.

In Stage 4, the conjugation of the BFC will be optimized in a designed experiment. Finally, in Stage 5, process options will be prioritized and evaluated.

A brief outline of the stages in the plan is given below.

1. Stage 1 — Review previous work

a. MSKCC (McDevitt)

b. ORNL

c. Dow Chemical

2. Stage 2 — Complexation w/ DOTA

a. Purify 2z Ac

b. Complex ORNL 225AC w/ DOTA (designed experiment)

c. Complex purified 225AC w/ DOTA (optimum conditions)

d. Interim report

3. Stage 3 — Complexation with BFC

a. Stability of SCN-Bz-DOTA under optimum complexation conditions

b. Complex 225AC w/ SCN-Bz-DOTA or

c. Explore use of NH2-SCN-DOTA

d. Interim report

4. Stage 4 — Conjugation

a. Optimize BFC conjugation to HuM195 using tracelnLu

b. Interim report

5. Stage 5 — Label HuM195 w/ 225AC

a. Propose & prioritize process options

b. Evaluate proposed process(es)

c. Final report

|

IsoTherapeutics Group, LLC

|

CONFIDENTIAL |

Page 5 of 10 |

| Propodal for API |

3/30/2007 |

Study Proposal - Details

Additional detail for the staged proposal follows. Proposed deliverables for each Stage are listed. It is understood that, with mutual agreement, these details will evolve as the project progresses. Additionally, deliverables and funding will be agreed upon prior to the initiation of each stage.

Stage 1— Review previous work

In this stage, all available data from prior work on the optimization of 225AC labeling will be reviewed. The data will come from various sources; API, MSKCC, ITG, and Dow. It is understood, however, that ITG (former Dow employees who worked on this problem while at Dow) does not have direct access to Dow confidential information.

This stage will be performed at no charge and is, in fact currently underway.

Deliverables:

1. Defined plan to move forward

Stage 2 — Complexation w/ DOTA

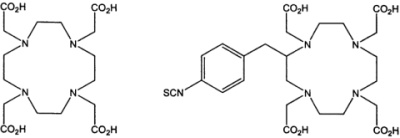

In this stage, the complexation of 225AC will be optimized in a designed experiment. Parameters to be explored are pH, time, temperature, concentration, and buffers. DOTA will be used as a surrogate for the BFC SCNBz-DOTA. The BFC has a reactive isothiocyanate group (SCN-) to attach to a lysine residue on the mAb. The presence of this SCN- group would complicate the experiments on optimizing the complexation conditions. As can be seen from the structures in Figure 2 below, the chelating portion of the BFC is DOTA.

Consideration will be given to the potential sensitivities of the SCN- moiety (in the case of complexation first) or of the mAb (in the case of conjugation first) when optimum conditions are decided upon.

In parallel with this designed experiment, we will attempt to purify 225Ac of any metallic contaminants that could potentially interfere with the chelation. Metal-specific resins may be employed to accomplish this. The purified 225AC will then be complexed with DOTA and these results compared to those above with the unpurified 225AC. Alternate sources of 225Ac may also be examined. The estimated cost to API for Stage 2 is $37,000.

|

IsoTherapeutics Group, LLC

|

CONFIDENTIAL |

Page 6 of 10 |

| Propodal for API |

3/30/2007 |

Figure 2. Structures of DOTA and the BFC SCN-Bz-DOTA

Deliverables:

1. Optimum 225Ac-DOTA complexation conditions defined

2. Interim report

Stage 3 - Complexation w/ BFC

In this stage the stability of the BFC will be examined under the conditions determined to be optimum for complexation. This will be important if complexation is done prior to conjugation. If the SCN- survives these conditions, then 225AC will be complexed with the BFC to verify these conditions. If stability of the BFC is an issue, i.e. if the SCN- moiety is hydrolyzed to a significant extent under the complexation conditions, then the use of NH2-Bz-DOTA will be explored. This is the precursor to SCN-Bz-DOTA which can be made in situ during the conjugation reaction. The estimated cost to API for Stage 3 is $33,000.

Deliverables:

1. Assessment of SCN-Bz-DOTA stability

2. Complexation conditions for either SCN-Bz-DOTA or NH2-Bz-DOTA

3. Interim report

Stage 4 - Conjugation

Using 177Lu as a tracer, the conjugation conditions for the BFC (either SCN-BzDOTA or NH2-Bz-DOTA) will be optimized in a designed experiment. Parameters to be varied may include pH, time, temperature, concentration, and buffers. Consideration will be given to the known stability of the HuM195 mAb. Determination of immunoreactivity of the mAb (e.g. by ELISA) is not part of this proposal but may be optionally added.

|

IsoTherapeutics Group, LLC

|

CONFIDENTIAL |

Page 7 of 10 |

| Propodal for API |

3/30/2007 |

The trace 177Lu will allow the determination of conjugation yield and average loading value (ALV), i.e. the number of BFCs per mAb. Optionally, the conjugation yield and ALV can be determined using MALDI-TOF mass spectrometry. This is not a part of this proposal, but may be added with mutual agreement. The estimated cost to API for Stage 4 is $21,000.

Deliverables:

1. Optimum conjugation conditions

2. Interim report

Stage 5 - Label HuM195 w/22AC

In this stage, options for 225Ac labeling of HuM195 will be proposed and prioritized. These options include process order (complexation-conjugation or conjugation-complexation) and conditions for complexation and conjugation. The preferred process will be evaluated. The estimated cost to API for Stage 5 is $21,000.

Deliverables:

1. Defined process maximizing the 225Ac labeling yield

2. Final report

ITG Consultation Services

At the request of API, ITG is willing to provide consultation services in areas not specifically delineated in this proposal, e.g. technology transfer or manufacturing oversight. These services will be performed at an hourly rate of $200.

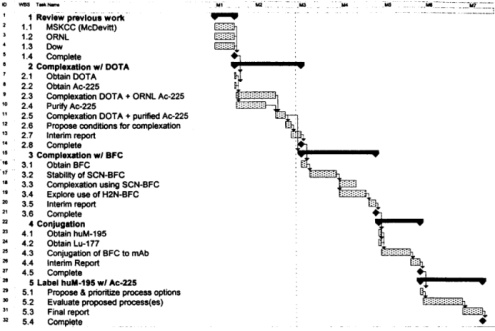

Time Estimate

The estimated time required for the various stages of this proposal is indicated in the Gantt chart in Figure 3 below. It is understood that this is an estimate and that scope changes and unforeseen issues may affect the timeline.

|

IsoTherapeutics Group, LLC

|

CONFIDENTIAL |

Page 8 of 10 |

| Propodal for API |

3/30/2007 |

Figure 3. Gantt Chart

Cost Estimate and Payment Schedule

Cost Estimate

The cost estimate for the stages of this project is given in the table below. It is understood that, with mutual agreement, scope changes may result in modifications to this estimate.

| |

|

M&S

|

|

|

Labor

|

|

|

Other

Expenses

|

|

|

Total

|

|

|

1. Review previous work

|

|

$ |

- |

|

|

$ |

- |

|

|

$ |

- |

|

|

$ |

- |

|

|

2. Complexation w/ DOTA

|

|

$ |

2,000 |

|

|

$ |

30,000 |

|

|

$ |

5,000 |

|

|

$ |

37,000 |

|

|

3. Complexation w/ BFC

|

|

$ |

2,000 |

|

|

$ |

28,000 |

|

|

$ |

3,000 |

|

|

$ |

33,000 |

|

|

4. Conjugation

|

|

$ |

3,000 |

|

|

$ |

18,000 |

|

|

$ |

- |

|

|

$ |

21,000 |

|

|

5. Label HuM195 w/ Ac-255

|

|

$ |

- |

|

|

$ |

21,000 |

|

|

$ |

- |

|

|

$ |

21,000 |

|

|

Total

|

|

$ |

7,000 |

|

|

$ |

97,000 |

|

|

$ |

8,000 |

|

|

$ |

1 112,000 |

|

Consultation work outside the above defined stages will be performed at a cost of $200/hour.

|

IsoTherapeutics Group, LLC

|

CONFIDENTIAL |

Page 9 of 10 |

| Propodal for API |

3/30/2007 |

Payment Schedule

Payment by API to ITG for each stage will be made as follows:

50% prior to initiation of each stage

50% upon completion of the final deliverable for that stage

Deliverables and cost will be mutually agreed upon prior to initiation of each stage. The final deliverable will be a report on the work done during that stage.

Fees for consultation services, if used, will be billed monthly.

Payment is due on receipt of invoice.

Signatures

Agreed upon and accepted by:

| /s/ Howard S. Wachtler |

Date |

5/4/07 |

/s/ R. Keith Frank, Ph.D. |

Date |

1/26/07 |

|

HOWARD S. WACHTLER

PRESIDENT & CEO

|

|

|

R. Keith Frank, Ph.D.

PRESIDENT & CEO

|

|

|

| Actinium Pharmaceuticals, Inc. |

|

|

IsoTherapeutics Group, LLC

|

|

|

|

IsoTherapeutics Group, LLC

|

CONFIDENTIAL |

Page 10 of 10 |